Are you curious about the main purpose of stacking racks? They are essential storage tools that maximize space and organize items in warehouses and logistics facilities.

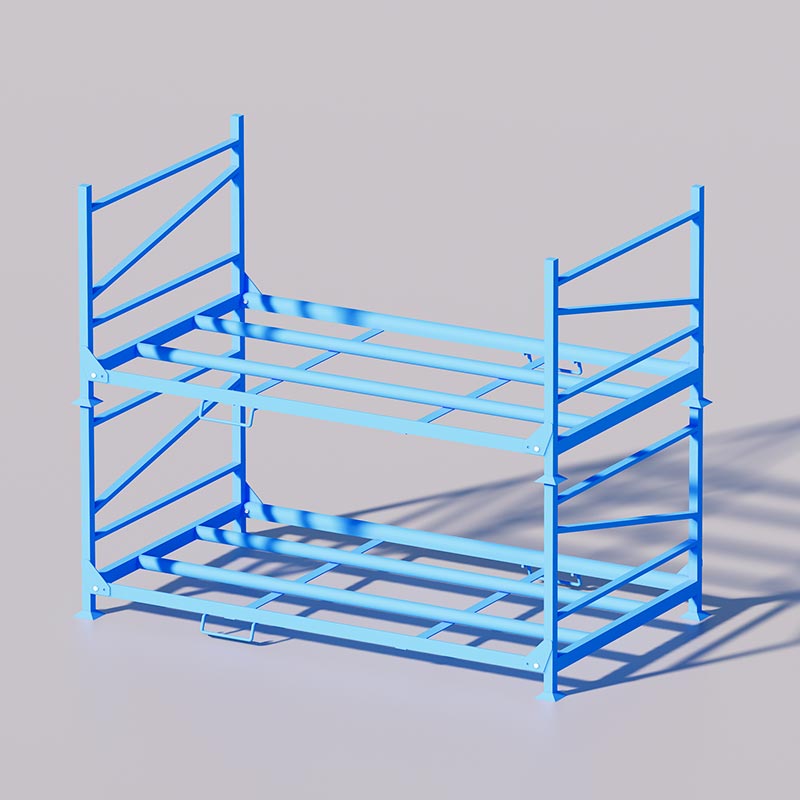

Stacking racks are designed for vertical storage and stacking of pallets or non-palletized goods. They help make the most of vertical space, increase storage density, and provide flexible storage options without permanent installation. These racks are widely used in manufacturing, cold storage, automotive industries, and distribution centers to efficiently organize products and optimize warehouse space.

Stacking racks simplify the cargo handling process, allowing for four-way forklift (manual forklift) access, facilitating unit load handling, enabling quick loading and unloading, and contributing to improved warehouse operational efficiency; they are also quick and easy to operate and offer high operational safety.

How Much Weight Can Stacking Racks Hold?

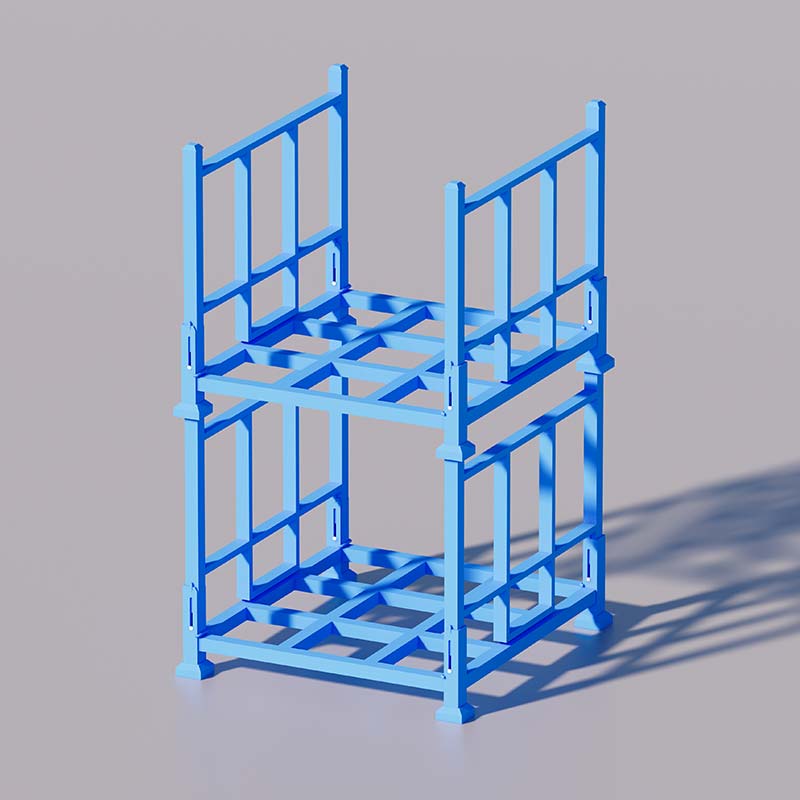

The weight capacity of stacking racks varies depending on the design and materials used. Usually, each rack can support between 1 to 1.5 tons. The number of layers you can stack depends on the structural design and warehouse height.

Typically, stacking racks are built to support 4-5 layers when properly assembled and used within their rated capacity. Reinforced corner posts and stable bases ensure safety and durability. To maximize safety and lifespan, never exceed the manufacturer’s recommended load per shelf or overall stacking height.

| Rack Type | Typical Load Capacity | Max Stacking Layers | Notes |

|---|---|---|---|

| Standard steel stacking racks | 1-1.5 tons per level | 4-5 layers | Suitable for most warehouse needs |

| Cold storage racks | Same as above, with corrosion protection | Same as above | Designed for low-temp environments |

Are Stacking Racks Suitable for Cold Storage?

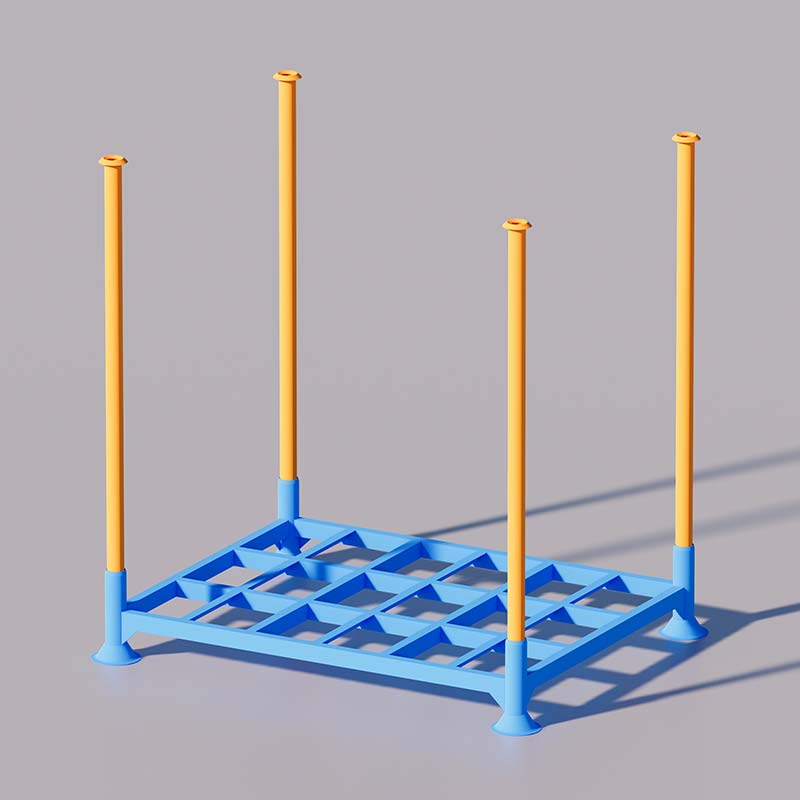

Yes, stacking racks are very suitable for cold and freezer storage environments. Many are made with galvanized or powder-coated finishes, which resist corrosion, humidity, and low temperatures.

Their material properties make them ideal for cold storage facilities, allowing for flexible space utilization in refrigerated warehouses. The design ensures stability in cold conditions and minimizes damage from moisture or rust. Because they can be easily disassembled or rearranged, stacking racks offer excellent adaptability for dynamic cold storage needs.

| Feature | Benefits |

|---|---|

| Zinc-plated or powder-coated finish | Corrosion and moisture resistance |

| Modular and easy to move | Flexibility for changing layouts |

| Support for multiple layers | Maximize vertical space |

How to Stack Racks Safely in Warehouses?

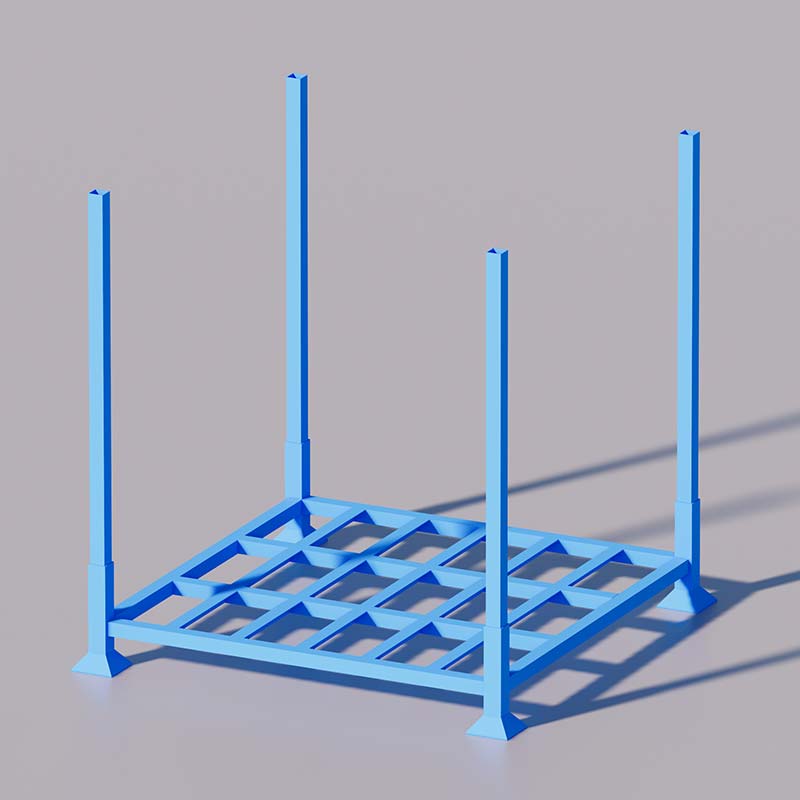

Safe stacking of racks requires careful planning and adherence to guidelines. First, always follow the manufacturer’s instructions regarding load limits and stacking height. Ensure that racks are erected on a flat, stable surface, and that all components are correctly assembled.

Use forklifts or stacking equipment properly to avoid tilting or damaging the racks. Maintain uniform load distribution across each level to prevent uneven stress and potential collapse. Always respect the maximum stacking height—generally 4-5 layers—and never exceed load capacities.

Perform regular inspections for signs of damage, corrosion, or misalignment. Reinforce or repair damaged parts immediately. When stacking multiple racks, ensure they are properly aligned and securely connected if designed for that purpose. Proper training for workers on safe handling and stacking techniques is essential to prevent accidents.

| Safety Tips | Best Practices |

|---|---|

| Follow manufacturer guidelines | Never exceed rated load |

| Use correct lifting equipment | Ensure even load distribution |

| Regular inspections | Look for rust, damage, or instability |

| Proper training | Reduce risk of accidents |

In summary, stacking racks are invaluable for maximizing storage efficiency, especially when used wisely and maintained properly to ensure safety in warehouses.