Cold Storage Racking One-stop Stacking Rack Supplier

Why Choose Our Product

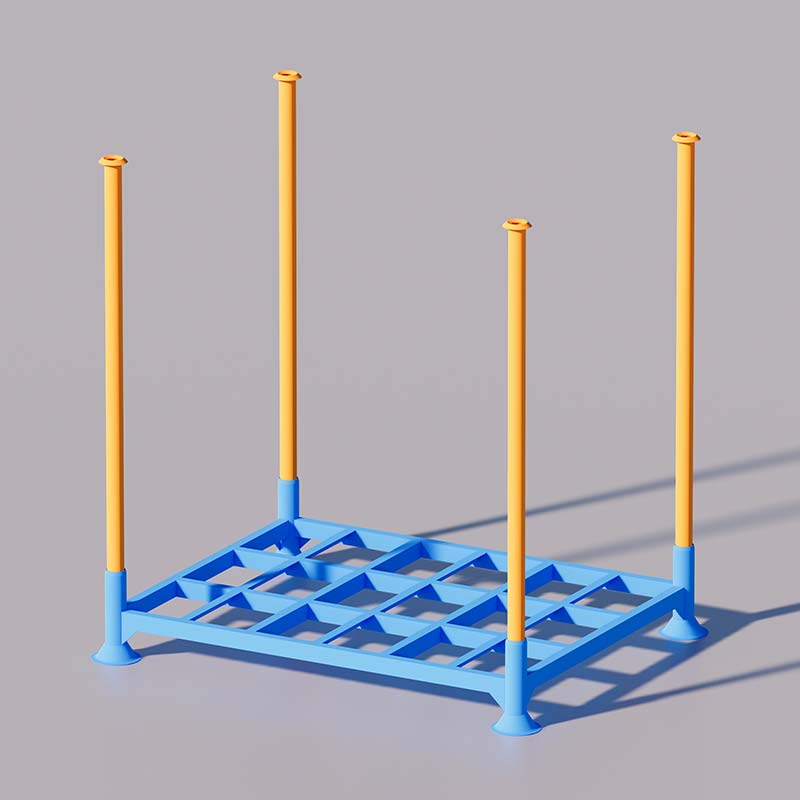

The Cold Storage Racking makes cargo stacking more flexible and portable. When used with a forklift, it can move cargo faster and more efficiently, accelerating the cargo logistics turnover.

Applicable Scenarios

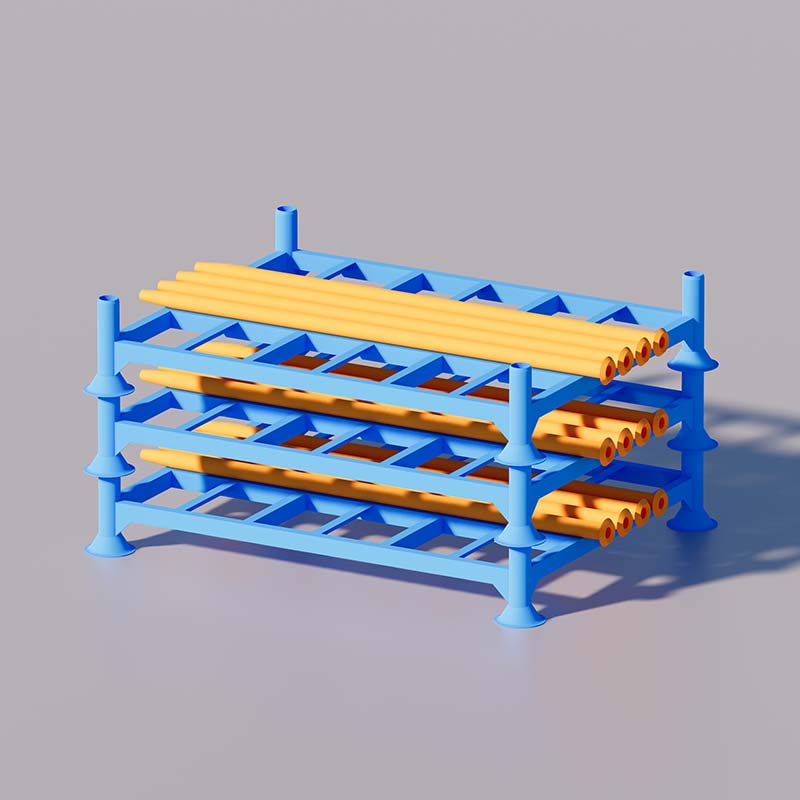

It can be used to stack a variety of goods, including tires, cold storage products, cloth rolls, steel pipes, etc., making the warehouse tidier and more convenient for goods to be put in and out of the warehouse.

Efficient storage

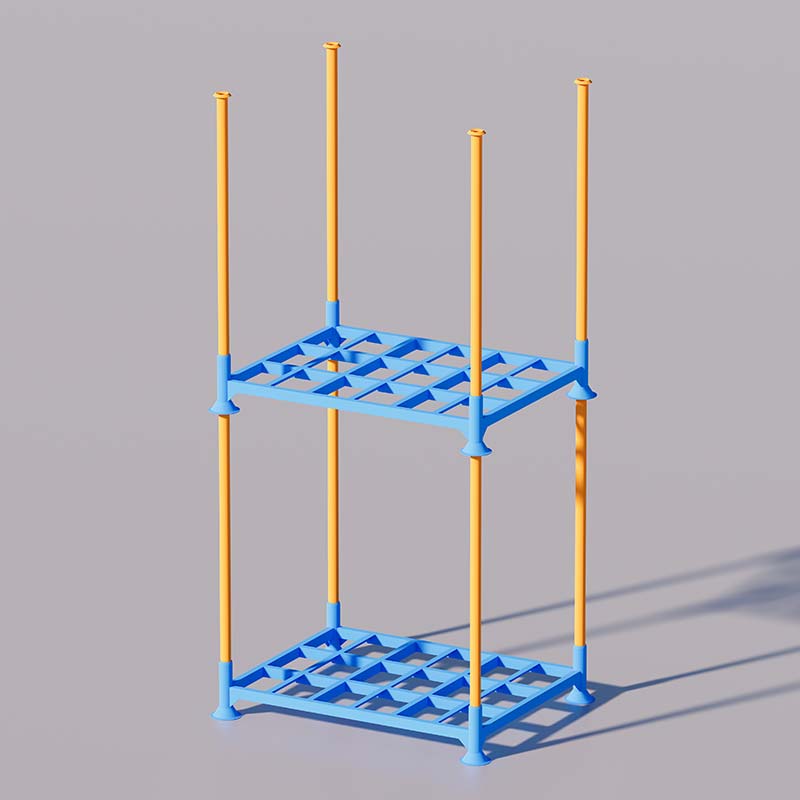

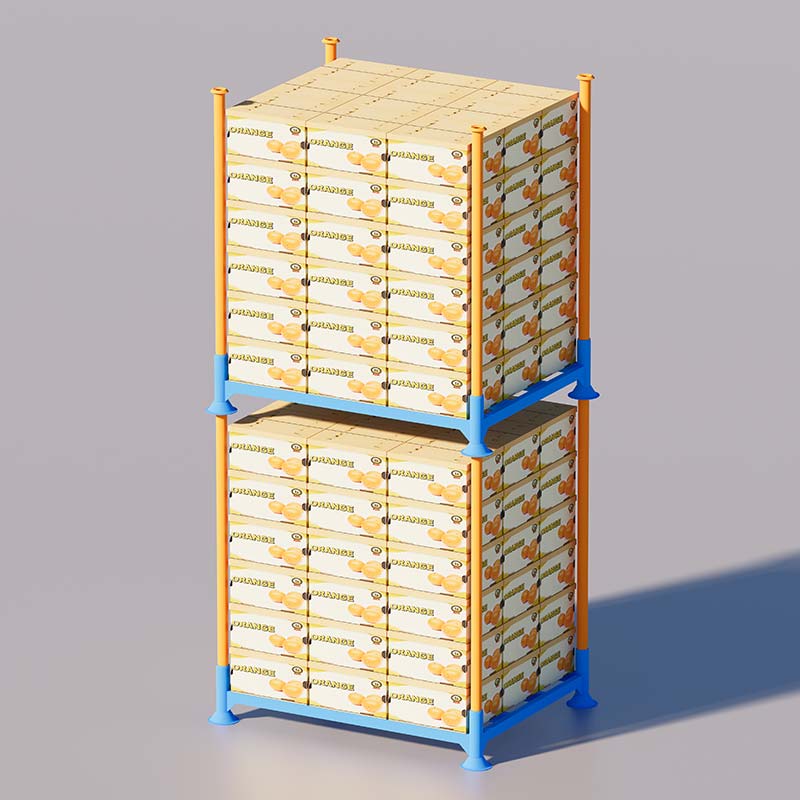

When loaded, up to 6 racks can be stacked to maximize the use of the upper space of the warehouse; when empty and folded, 20 racks can be stacked, and they can be folded or simply disassembled when idle to save warehouse space.

Features and Benefits

Mobile, Stackable, Foldable/removable sides:There is no need to install the shelf after receiving it. You only need to open the folding panel or insert the square tube to use it. It can be used with a forklift for storage and outbound transportation, which not only saves manpower but also improves operational safety.

Product Applications

Discover the versatile ways our product can be used in various settings and scenarios.

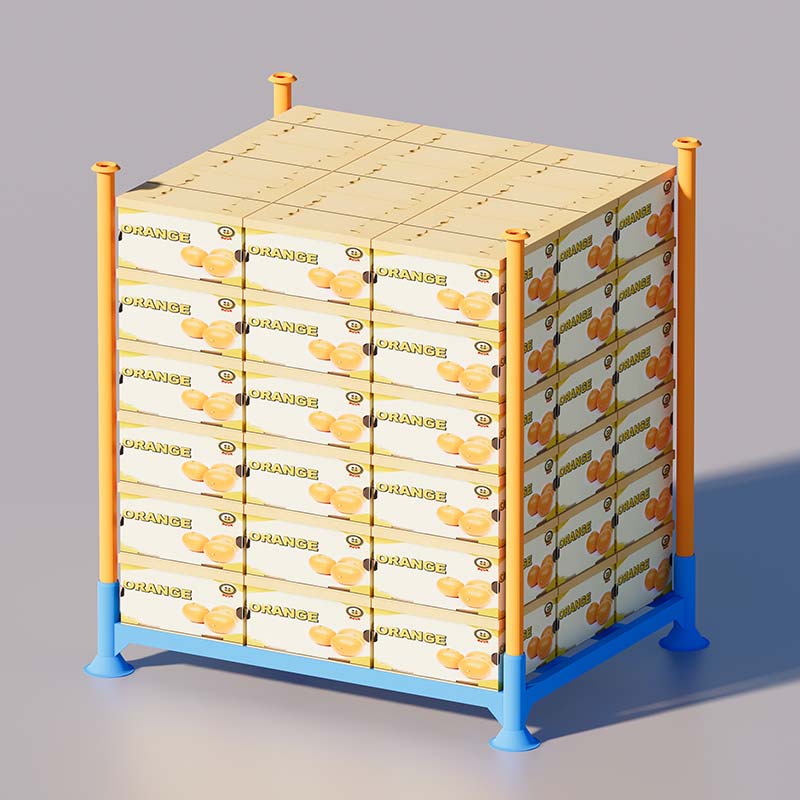

Agricultural Products

The company was provided with galvanized stacking racks that can adapt to the temperature of cold storage. When used with forklifts, single loading and unloading time was reduced to 5 minutes, the packaging damage rate was reduced by 12%, and space utilization was increased by 35%.

Frozen Food

The seafood processing plant was provided with stacking racks that can be flexibly stacked for storage, helping it achieve high-density storage and increase space utilization by 30%. When used with forklifts, labor costs are greatly saved.

Fruits and Vegetables

The cold chain logistics company originally used wooden pallets, which had poor moisture-proof effect and could not secure goods. Later, it adopted stacking racks, which are moisture-proof and rust-proof, and also have a baffle design to prevent goods from falling, thereby improving safety.

Meet the Designer

Leon

Lead Product Designer

Leon has been deeply involved in efficient warehouse planning for over 10 years. Leveraging his professional methodologies, he has helped numerous companies around the world precisely optimize their warehouse processes and significantly improve warehouse operational efficiency. Internationally renowned companies like Michelin and Dole are among my core clients, developed through my initial collaborations and ongoing service development.

"In my warehouse optimization practice, I always prioritize user experience and the core attributes of the goods. Every step of my planning process is tailored to the specific needs of the scenario and the specific characteristics of the goods. I am passionate about resolving various warehouse pain points for my clients, from process bottlenecks to efficiency bottlenecks. Resolving these issues not only creates value for my clients, but also brings a strong sense of professional accomplishment and enjoyment."

Frequently Asked Questions

Find answers to common questions about our product.

Our stacking racks are welded with high-quality national standard steel, and the surface is electrostatically sprayed or galvanized; while ensuring the durability and practicality of the stacking racks, it also ensures their beautiful appearance.

The stacking rack is made of high-quality materials, with a stable structure and a load capacity of up to 1000kg/1500kg/2000kg.

Yes, the stacking racks can be stacked and used, and can be stacked 4-6 layers to achieve high-density storage.

Yes, stacking racks support personalized customization and can be customized according to the properties of the goods and usage habits.

Yes, we deliver our stacking racks to over 150 countries worldwide.

Still have questions? We're here to help!

Product Gallery

Explore our product from every angle with these high-quality images.