What Is OSHA's Rule for Pallet Stacking Racks?

Are you unsure about OSHA's stance on stacking racks? OSHA doesn't have a single rule but a set of standards and guidelines to ensure safety and stability.

OSHA primarily uses 29 CFR 1910.176(b), which states that materials stored in tiers must be stacked, blocked, or interlocked to prevent sliding or collapsing. Additionally, OSHA relies on the "General Duty Clause" to cite hazards not covered by specific standards, often referring to ANSI/RMI MH16.1 for rack design and maintenance. Regular inspections, both annual professional checks and daily internal inspections, help maintain safety by catching dents or damage early.

There isn’t an exact height limit set by OSHA. Instead, height is governed by stability and fire safety. The material must not lean or appear unstable, and in accordance with NFPA 13, there should be at least 18 inches clearance between the top of stored items and sprinkler heads. For idle pallets, the recommended maximum stack is 15 feet to avoid accidents. OSHA emphasizes stability, proper blocking, and fire safety over specific height restrictions.

How High Can You Legally Stack Racks?

There is no fixed legal maximum height for stacking racks under federal OSHA rules. Instead, height limits are determined by two key factors: stability and fire safety.

If a stack leans or appears unstable, it is too high regardless of its measured foot height. In terms of fire safety, the NFPA 13 sprinkler standard mandates that there must be at least 18 inches from the top of the stored goods to the sprinklers. For empty pallets or seasonal items, OSHA recommends a maximum stacking height of around 15 feet to prevent tipping or collapsing risks.

In practice, safety is about ensuring that the stack remains stable visually and structurally. Any taller or unstable stack can pose a hazard, and compliance must be judged based on stability, fire safety clearance, and best practices.

| Factor | What It Covers | Typical Limitations |

|---|---|---|

| Stability | Prevents leaning and tipping | No fixed height—depends on load and stability |

| Fire Safety (NFPA 13) | Maintains sprinkler clearance | Min 18 inches clearance; 15 ft for idle pallets |

Our stacking racks can safely stack your goods to a greater height.

What Is the Difference Between Racking and Stacking Racks?

Pallet racking and stacking racks serve different purposes and have distinct features.

Pallet racking is a fixed, permanent steel structure bolted to the floor. It’s designed for high-density, organized storage of uniform pallets and provides excellent stability. These racks are stationary, require installation and teardown in case of relocation, and are ideal for bulk storage of consistent products. Their stability is highly reliable because they are anchored to the building.

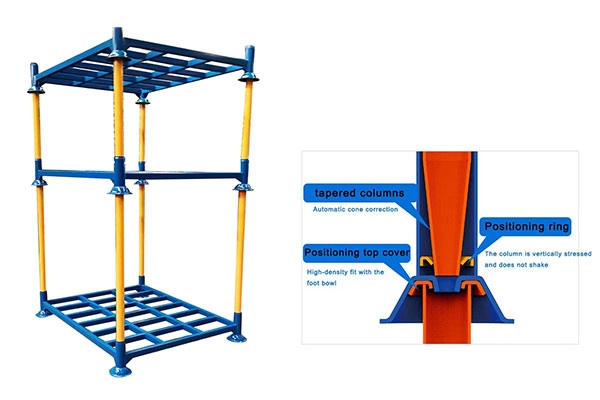

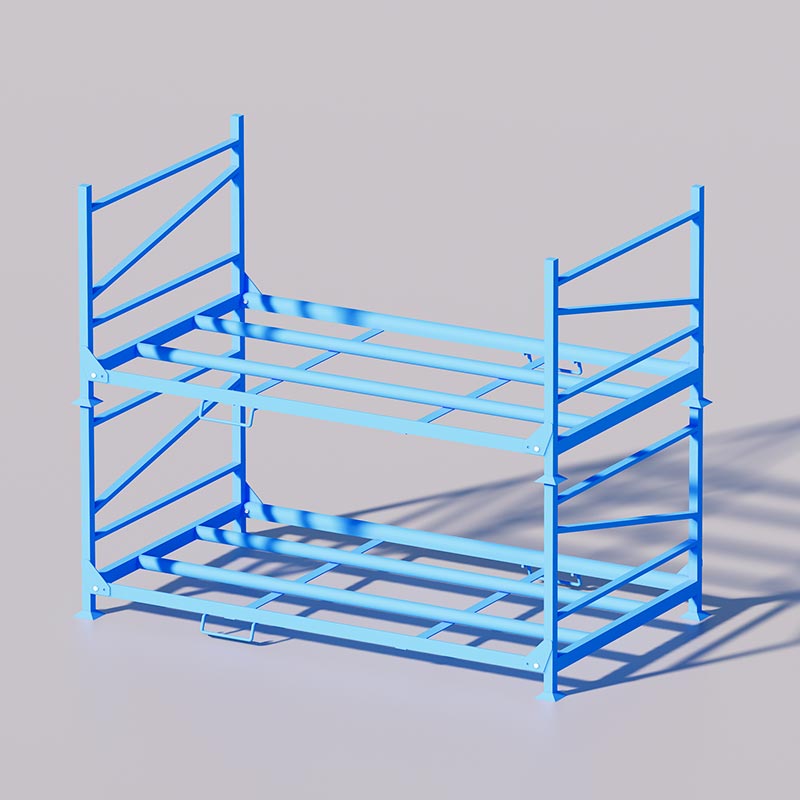

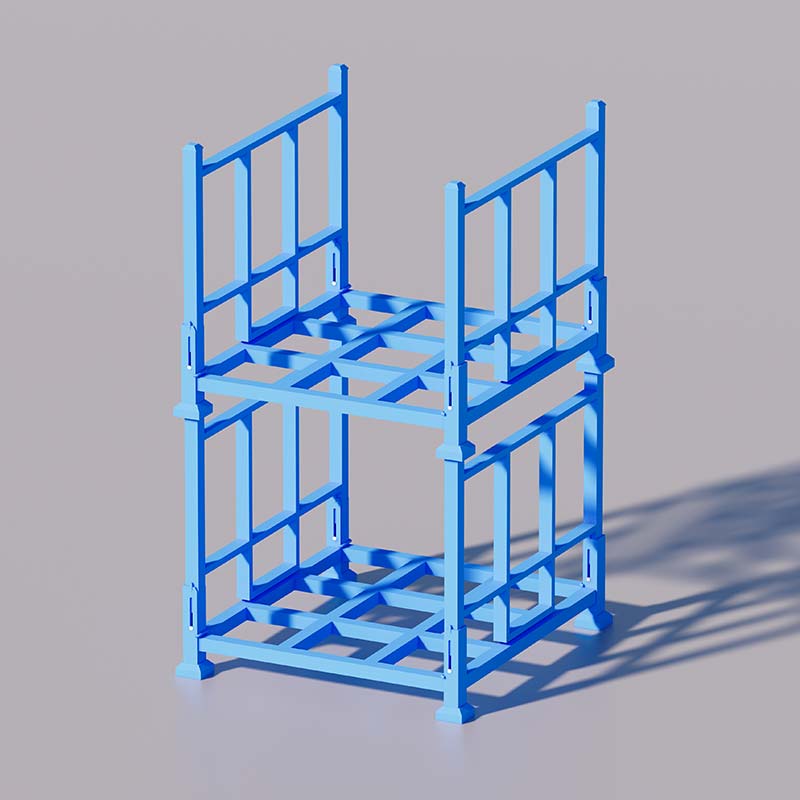

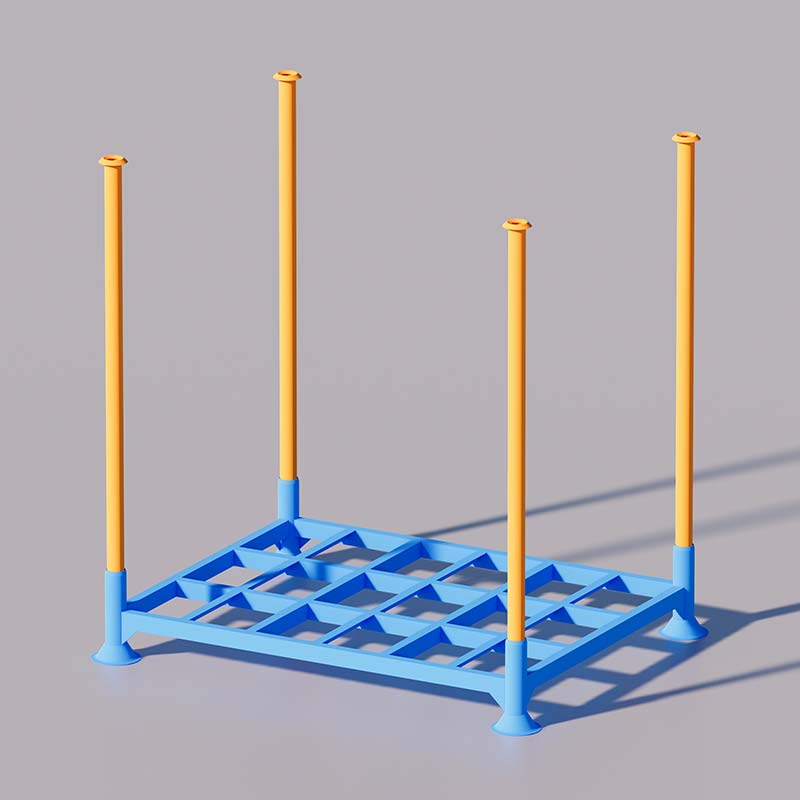

Stacking racks, on the other hand, are modular, portable frames that can sit atop each other. They are easy to move using a forklift and can be nested or folded when empty, making them highly flexible. They are suitable for awkward loads like tires or pipes, or seasonal inventory that changes frequently. The design includes precision-molded caps and flared bases that ensure safety and stability even when stacked multiple layers.

| Feature | Pallet Racking | Stacking Racks |

|---|---|---|

| Structure | Fixed, bolted to the ground | Modular, portable, can nest or fold |

| Flexibility | Stationary, permanent | Movable, adaptable to seasonal changes |

| Best Use | High-density, uniform pallets | Irregular loads, seasonal inventory |

| Stability | Very high (anchored to the building) | High (stacking design for safety when nested) |