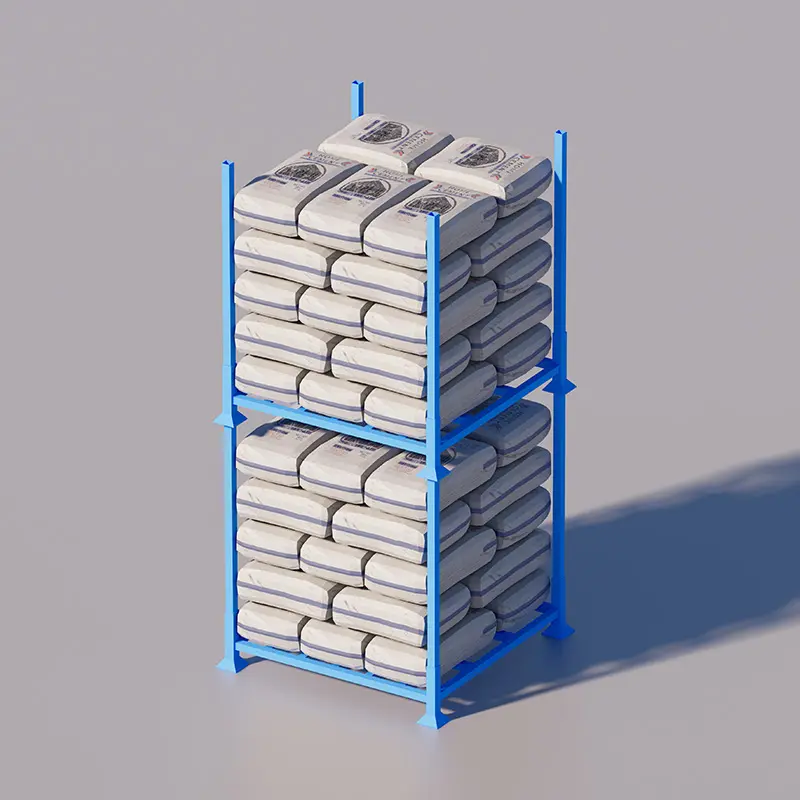

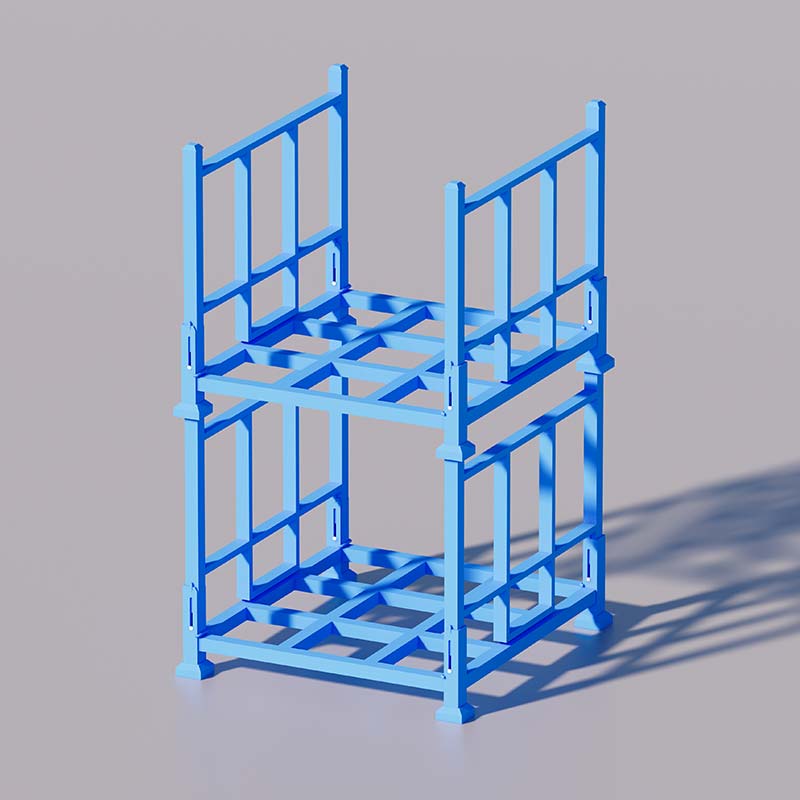

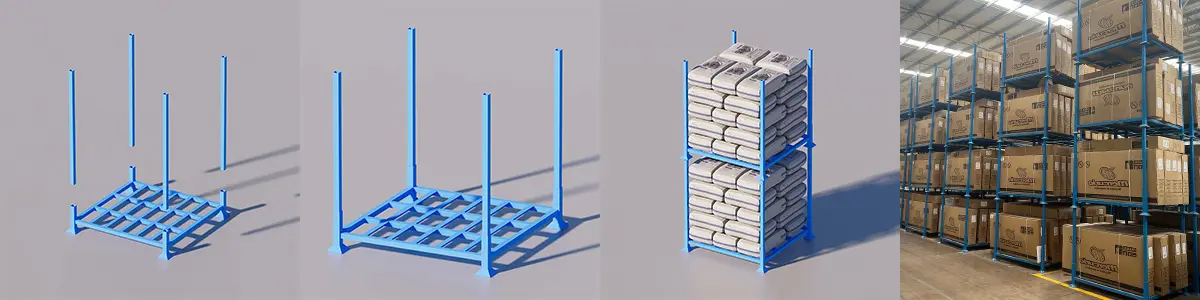

Sqaure Tubes Stacking Rack with Bagged Products

Model

Rex Metal - Stacking Rack

Size

1200×1200×1500 mm

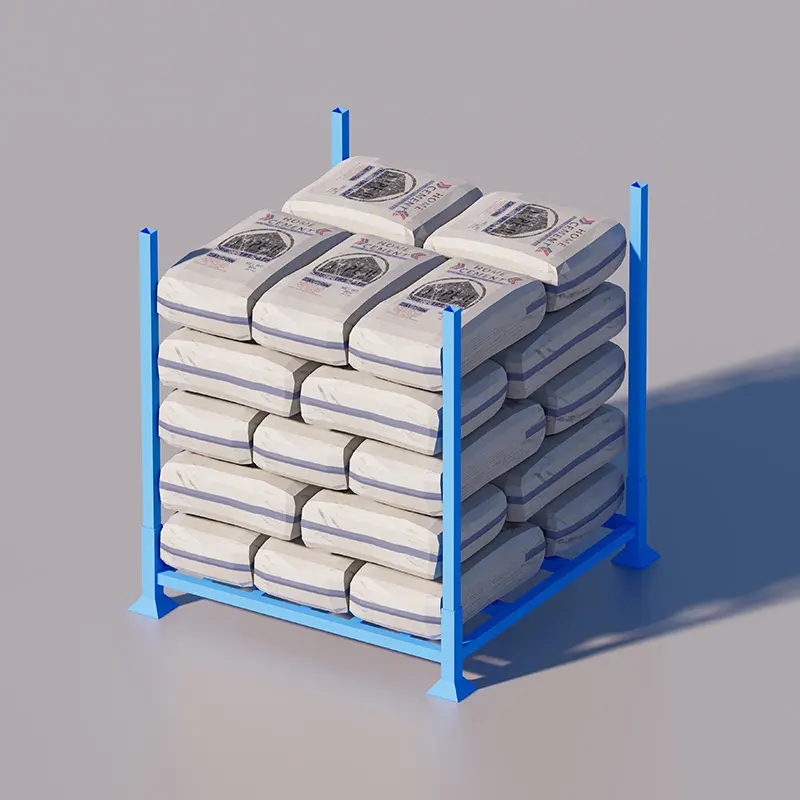

Cargo Types

Bagged goods, boxed goods, groceries and other items stacked in the warehouse

Customized

Customization supported

Specifications & Usage Instructions

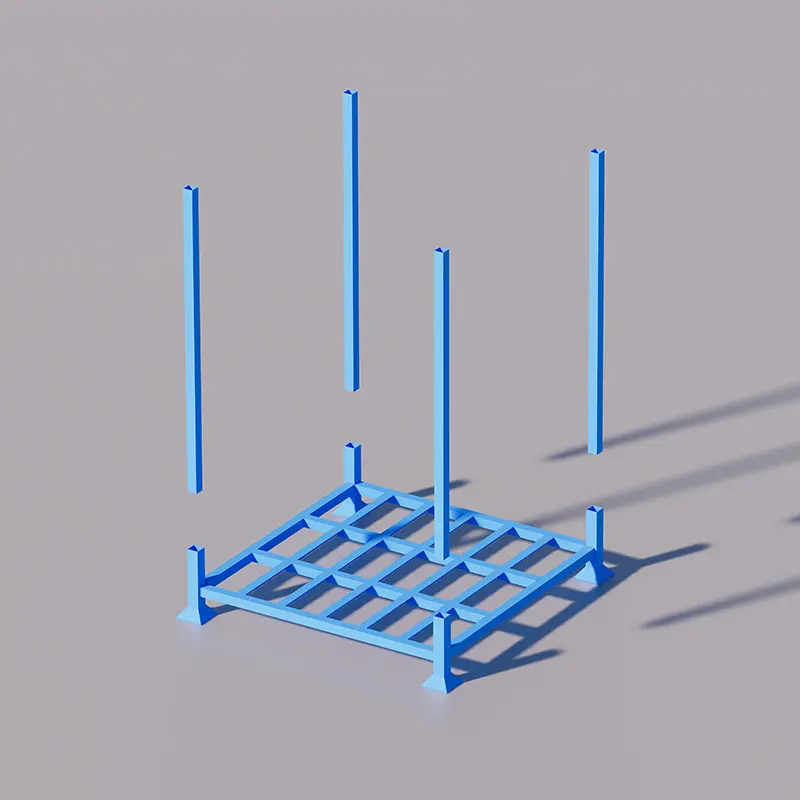

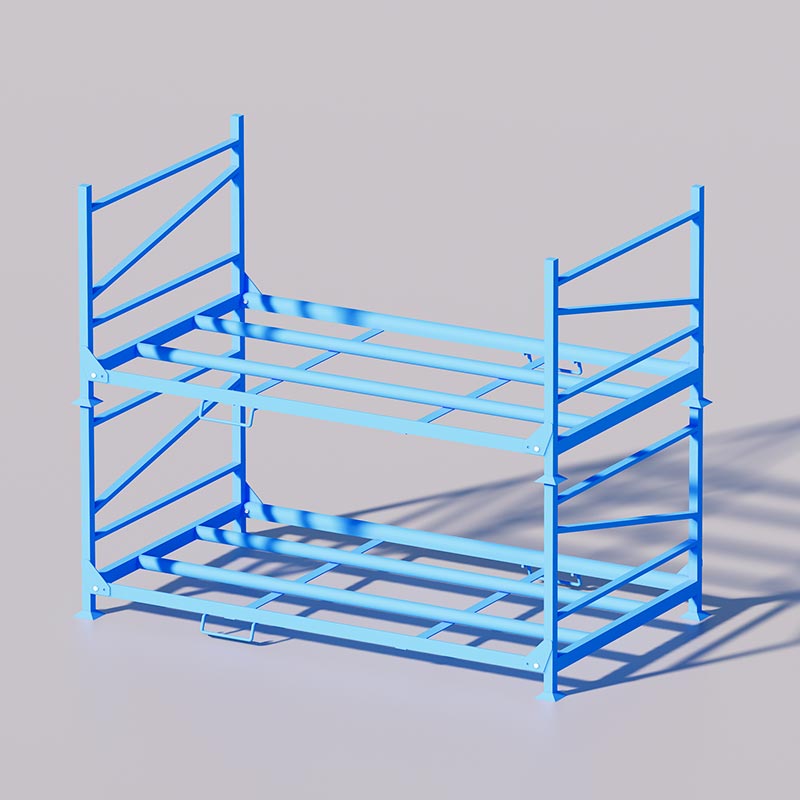

| Type | Detachable | Materials | Square steel pipe (Q235) |

| Features | Mobile、 Stackable | Load capacity | 1000kg |

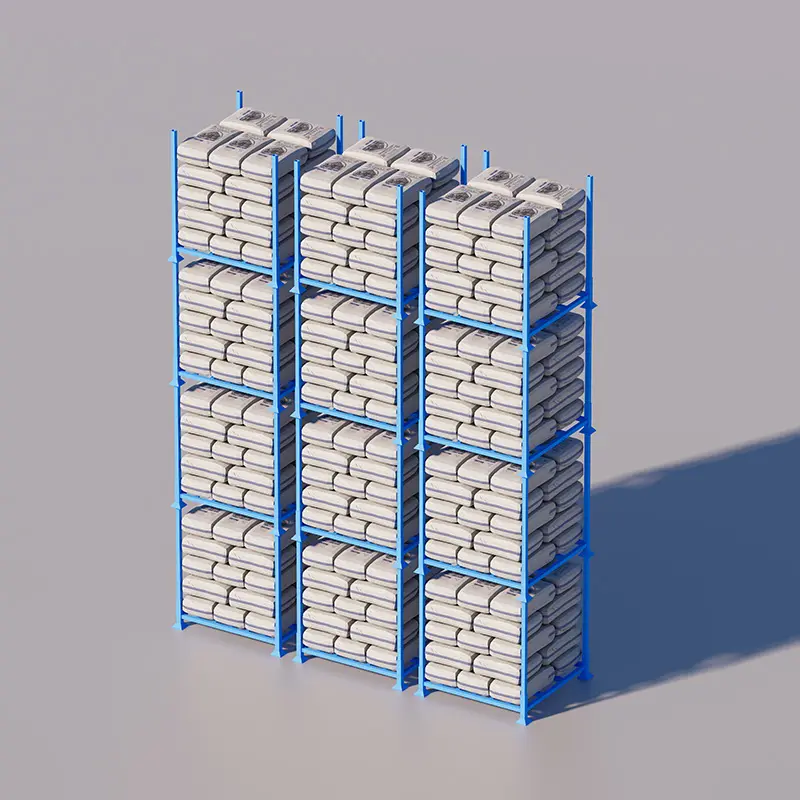

| Finish | Powder coated paint | Stackable – max. quantity (open) | 4 |

| Color | Blue | Stackable – max. quantity (closed) | 20 |

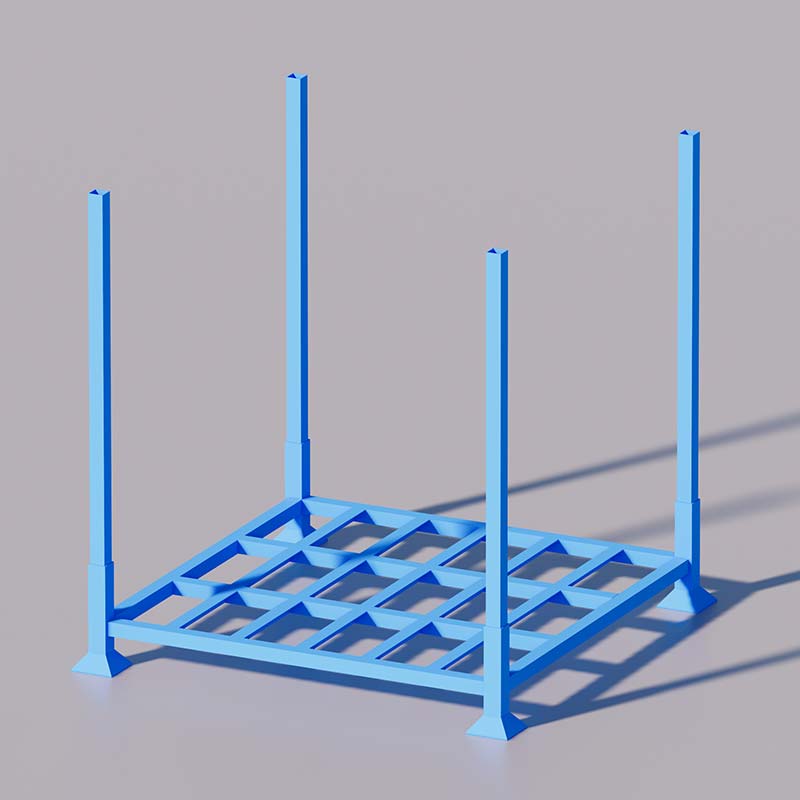

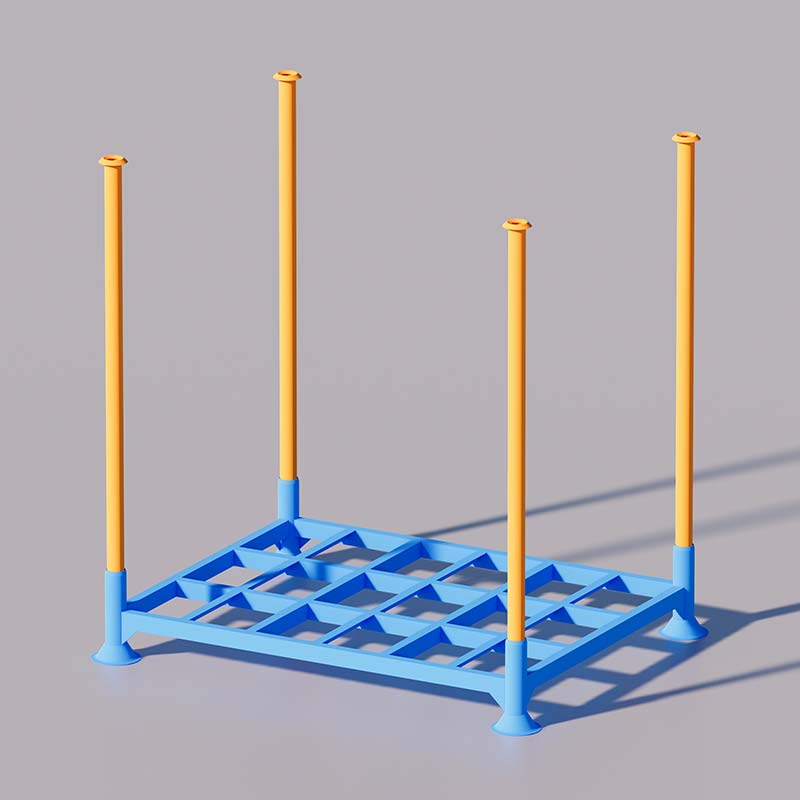

Installing Support Fittings:

Align one end of the square/round tube with the frame sleeve and insert it horizontally to the bottom (ensure full insertion).

Placing Goods:

Stack goods on the stacking rack.

Forklift Stacking:

Adjust the forklift forks to match the bottom of the frame. Slowly insert the forklift forks into the bottom of the stacking rack until fully in place. Lift the rack at a steady speed to stack the goods. When lowering, gently place the goods onto the lower rack, ensuring the edges are aligned.

Using stacking racks can make full use of the upper space, improve the utilization rate of the upper space in the warehouse, and achieve high-density storage.

Overview

Square tube stacking racks are stackable storage devices with square steel tubes as the main structure, specifically designed to solve problems such as limited warehouse space and low storage and retrieval efficiency. Their robust structure and high load-bearing capacity allow for multi-level stacking to achieve three-dimensional storage, increasing space utilization by 2-3 times.

Stacking racks can also be used in conjunction with forklifts, pallet jacks, and other transport tools for goods turnover, temporary storage, and long-term storage.

The surface is typically treated with powder coating or galvanizing, providing excellent rust and corrosion resistance, making them suitable for ambient temperature warehouses, workshops, logistics centers, and outdoor temporary storage scenarios.

Advantages

Ⅰ. The plug-in core structure allows for tool-free assembly and disassembly, enabling quick operation by a single person and improving warehousing efficiency.

Ⅱ. It supports multi-layer vertical stacking, maximizing the use of vertical storage space and significantly reducing floor space requirements.

Applications

I. Warehousing and Logistics Industry:

1. Zoning and stacking of goods significantly improves warehouse utilization.

2. Suitable for distribution centers, e-commerce warehousing, and third-party logistics.

3. Manufacturing and factory workshops.

4. Suitable for storing parts, semi-finished products, and raw materials.

5. Flexible use as temporary shelving or turnover racks.

II. Textile Industry: Commonly used for storing fabric rolls, textiles, and clothing packaging; stable structure prevents goods from being crushed or deformed.

III. Food and Packaging Industry: Used for stacking and storing packaging materials, turnover boxes, and cardboard boxes.

IV. Automotive Parts and Hardware: Suitable for heavy materials, metal parts, stampings, castings, and other high-load items.

V. Outdoor Temporary Storage: Galvanized for direct use in outdoor construction sites, temporary warehouses, and other similar scenarios.