What Are Stack Racks for Cold Storage Warehouses?

Need a reliable solution for storing frozen goods efficiently? Stack racks designed for cold environments can boost capacity and optimize space in your cold storage.

Stack racks for cold storage are sturdy, specially coatings steel shelves that can withstand freezing conditions. They are used to store frozen food, seafood, vegetables, and dairy products safely while maximizing space and ensuring easy handling.

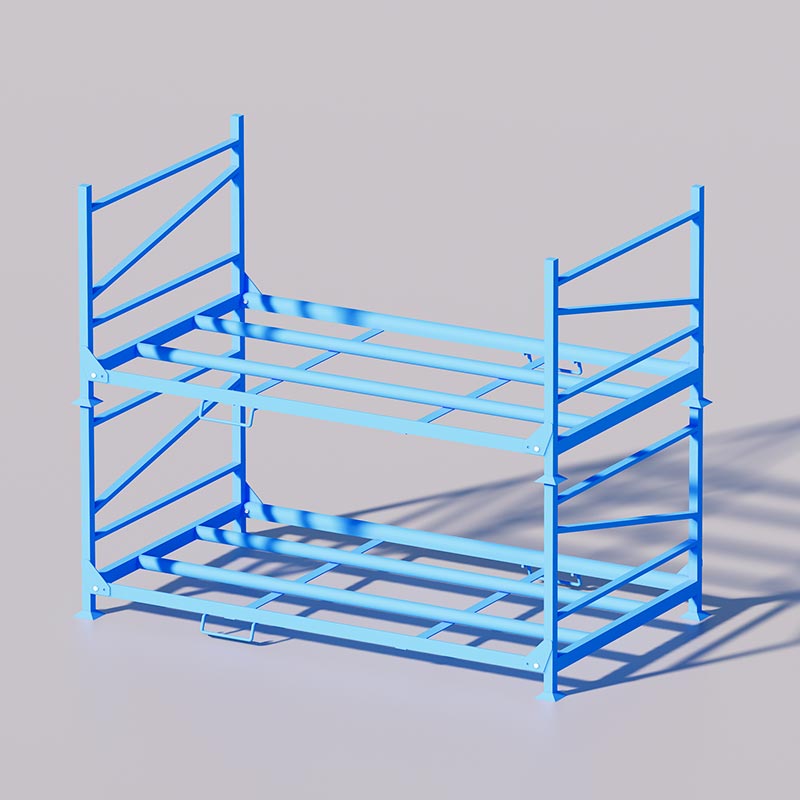

These racks are made from galvanized or powder-coated steel, which makes them highly resistant to rust and corrosion in freezing environments. They do not need to be fixed to the floor and are easy to move and stack, allowing flexible use of vertical space. When not in use, they can be folded or nested to free up valuable cold storage space. These features make them ideal for storing perishable items like meat, seafood, and packaged frozen products, with a typical lifespan of 10-15 years if coated properly.

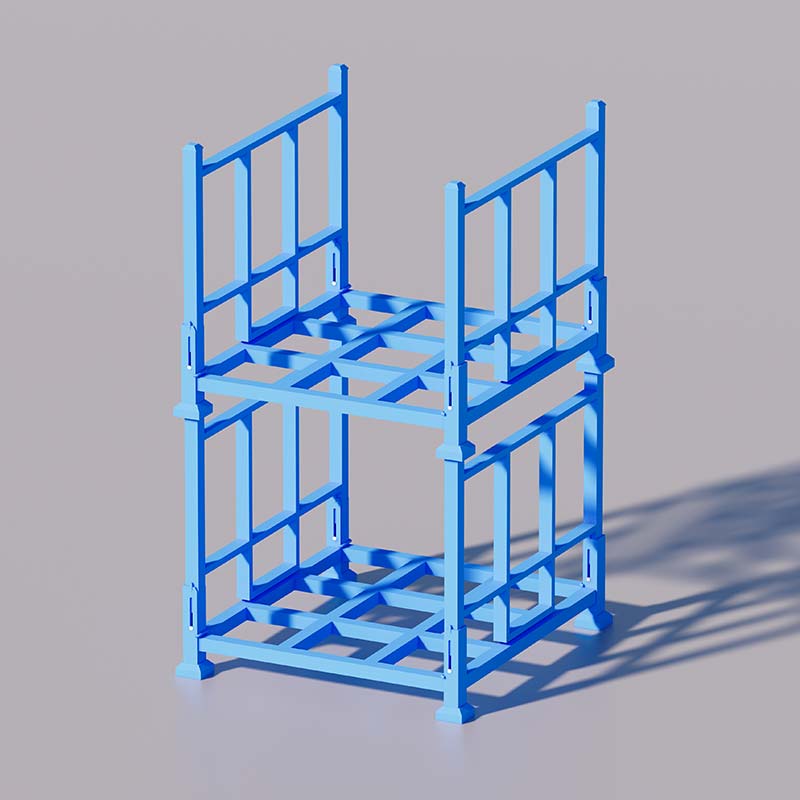

Stack racks significantly improve space utilization by enabling the stacking of pallets or containers up to 4-5 layers high. This means you can increase storage capacity by 200-300% compared to stacking pallets on the cold room floor. Using well-designed racks makes your cold storage more organized, easier to access, and reduces product damage.

What type of stack racks are best for cold storage environments?

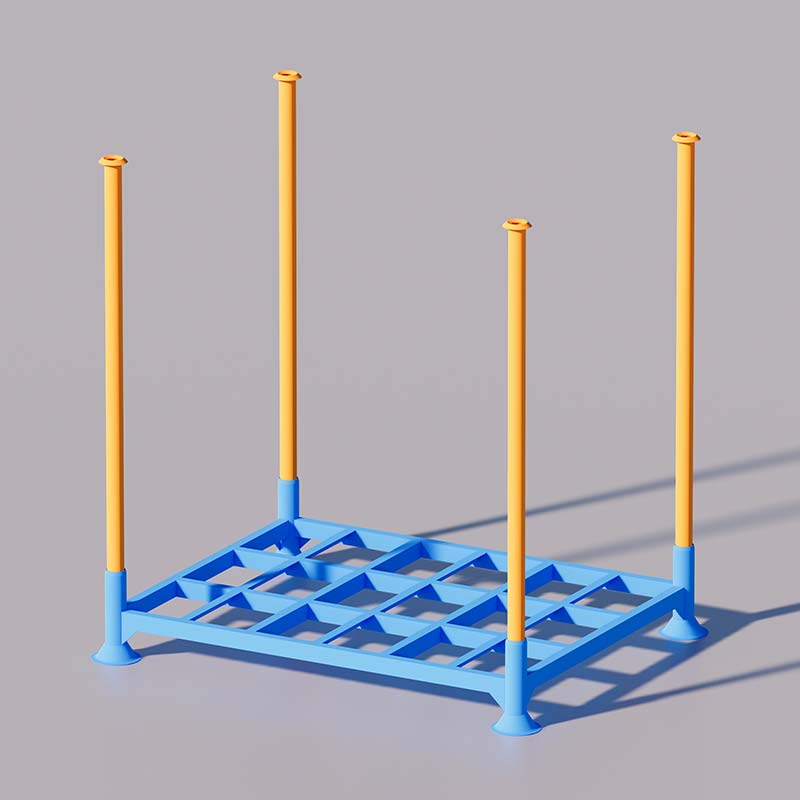

The best stack racks for cold storage are made from galvanized or powder-coated steel. These materials resist rust, corrosion, and damage caused by moisture and low temperatures. Their durable finish extends the lifespan, even in harsh, freezing conditions.

The racks should be engineered to handle heavy loads, such as pallets of frozen meat or seafood, with capacities typically ranging from 1000 to 3000 kg per layer. Customizable sizes are available to fit standard pallet dimensions like 1100×1100mm, ensuring perfect compatibility for efficient cold storage.

| Material | Resistance Features | Ideal For | Special Features |

|---|---|---|---|

| Galvanized Steel | Rust and corrosion resistant | Heavy-duty, high-moisture environments | Durable, anti-corrosion coating |

| Powder-coated steel | Moisture resistant, easy to clean | Flexible, general cold storage | Custom colors, aesthetic options |

How do stack racks improve space utilization in cold rooms?

Stackable racks significantly improve space utilization by using forklifts to stack goods upwards. Because they can be stacked 4-5 layers high, storage capacity can be effectively increased threefold within the same floor area.

For example, in a typical cold warehouse, storing pallets directly on the floor maxes out at two layers—about 1.2m×1.0m per pallet—occupying a lot of space and limiting storage volume. Using stack racks, you can store up to five layers, increasing the capacity from roughly 4,160 pallets to around 12,500 in the same space. This means not only more inventory but also better organization and easier access.

Furthermore, these racks have adjustable heights and customizable configurations, fitting different pallet sizes and weights. They allow efficient layout planning, reduce aisle space, and improve workflow. Their foldable or nesting features when not in use free up cold space, making the warehouses more flexible and productive.

| Traditional Storage | Storage with Stack Racks | Space Efficiency Gain |

|---|---|---|

| 2 layers max | 4-5 layers stacking | 200-300% increase |

| Floor-stored pallets | Vertical stacking | Better space utilization |

| Limited flexibility | Reconfigurable and foldable | More adaptable storage |

Are stack racks compatible with palletized frozen goods?

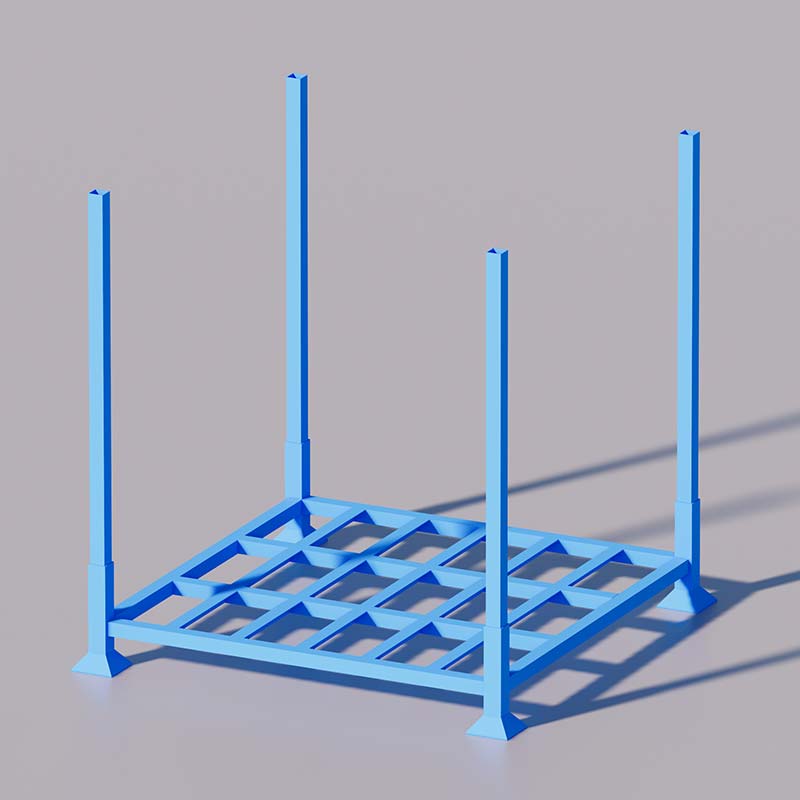

Yes. Stack racks are designed to support various standard pallet sizes, such as 1100×1100mm, and can handle different types of pallets—wooden, plastic, or steel. They are an ideal solution for storing palletized frozen goods because they keep products elevated, reducing deformation and damage caused by heavy stacking or moisture.

They also facilitate easy loading and unloading through forklifts or reach trucks from four directions, improving efficiency. The racks support the weight of frozen products safely, ensuring compliance with safety regulations and maintaining product integrity.

Because of their customizable design, these racks can be tailored to fit specific pallet heights and capacities, making them adaptable to different frozen and cold chain logistics needs. They are suitable for storing meat, seafood, vegetables, and ice-packed products, helping reduce damage and preserving freshness.

How do you prevent rust or corrosion on stack racks used in freezers?

The key is selecting racks made from galvanized or powder-coated steel. These materials have a protective coating that prevents rust and corrosion, even in the extreme cold and moisture-rich environments of freezers.

Regular maintenance, such as cleaning and inspections, also help prolong the racks’ lifespan. Applying anti-corrosion sprays or treatments periodically can further protect the surface from moisture buildup.

Design-wise, open-frame structures promote airflow around stored pallets, which dries out moisture and prevents corrosion from stagnation. When purchasing racks, ensure they have the proper coating, and avoid using uncoated or painted steel that is vulnerable to rust in freezing conditions.

By choosing high-quality coated steel racks and maintaining them properly, you can expect a lifespan of 10-15 years and reliable performance in even the harshest cold storage environments.

Want to explore more? Check out our range of cold storage racks here.