Many warehouse owners struggle with space and flexibility. They want a solution that allows easy movement and efficient storage. This is where mobile pallet racking1 comes into play, offering a smart way to maximize storage and boost productivity.

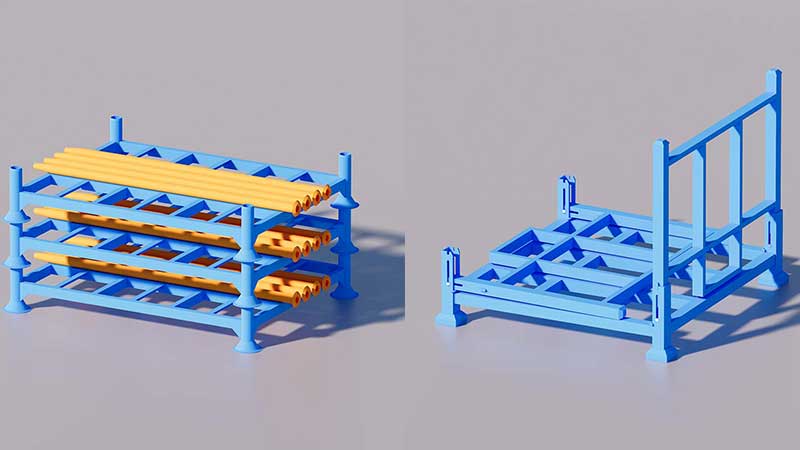

Mobile pallet racking is a type of storage system that can move within a warehouse space. Unlike fixed racks, these units are designed to be mobile, which means they do not need to be anchored to a permanent position. They are made as standalone units that can slide or be moved around with simple tools, like forklifts. This mobility makes it easier to access pallets when needed, without wasting space on aisles. These racks are usually composed of several columns and can be moved along tracks or on wheels. They support storing pallets vertically, offering a high-density storage solution. This flexibility allows warehouse managers to optimize space and improve storage efficiency.

How to stack pallets without racking?

Stacking pallets without using racks can seem straightforward but requires careful planning. Many people simply place pallets directly on the floor or stack them on top of each other. This method is quick but not always safe or efficient. It can take up too much space and create safety hazards if pallets fall over.

The alternative is to use stacking techniques2 that improve safety and space utilization. For example, you can use pallets with interlocking edges or stacking frames that stabilize the load. It's best to stack pallets in a uniform manner, stacking the heaviest ones at the bottom and lighter items at the top. You should also keep aisles clear for easy access and ensure that stacked pallets do not block exits or pathways.

Good organization helps to avoid damage to products and reduces fatigue for workers. Remember, stacking without racks is suitable for small quantities or temporary storage but not for long-term or high-density storage needs.

What is the difference between racking and stacking?

Understanding the difference between racking and stacking helps to choose the right storage method. Racking refers to structured storage systems like shelves or racks that are fixed or mobile. These are designed to hold pallets or products in designated places. Racking offers several advantages, including better organization, safety, and air circulation. It also allows for easier access and retrieval of items.

Stacking, on the other hand, is a more simple method. It involves placing pallets or items directly on top of each other or on the floor. While stacking can be quick and easy, it doesn’t offer the same level of organization or safetyfound in racking systems. Stacking is often less efficient in space utilization, especially for large quantities of goods, and poses safety risks if heavy pallets fall or collapse.

| In summary: | Feature | Racking | Stacking |

|---|---|---|---|

| Organization | High | Low | |

| Safety | High | Moderate to low | |

| Space efficiency | High | Low to moderate | |

| Flexibility | Fixed or move | Static |

Moving to a proper racking system can greatly improve your warehouse operations, especially as your inventory grows.

Can I install pallet racking myself?

Many warehouse operators wonder if they can set up pallet racking on their own. The answer is yes.

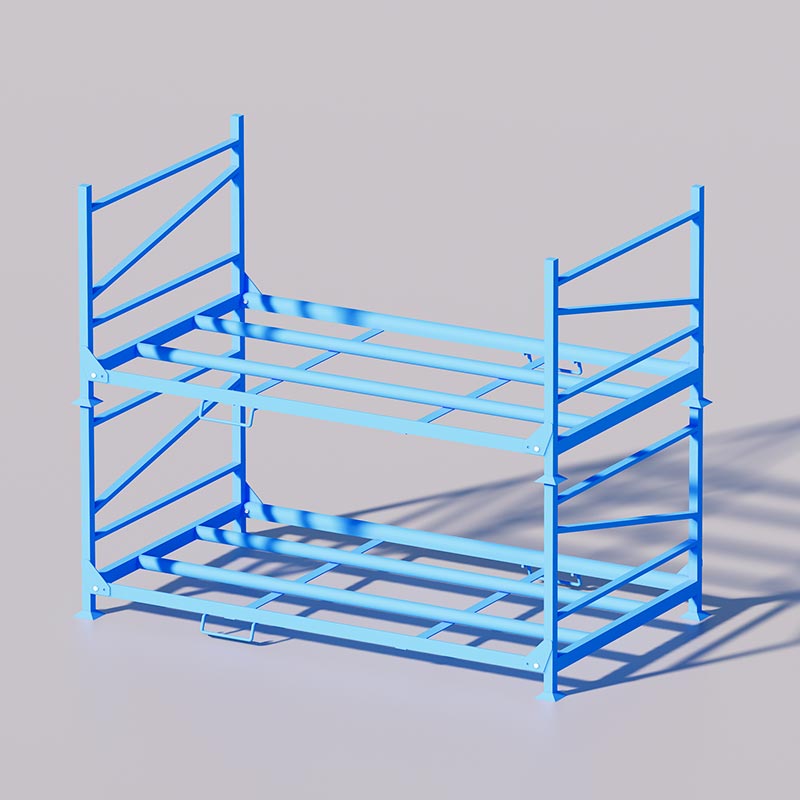

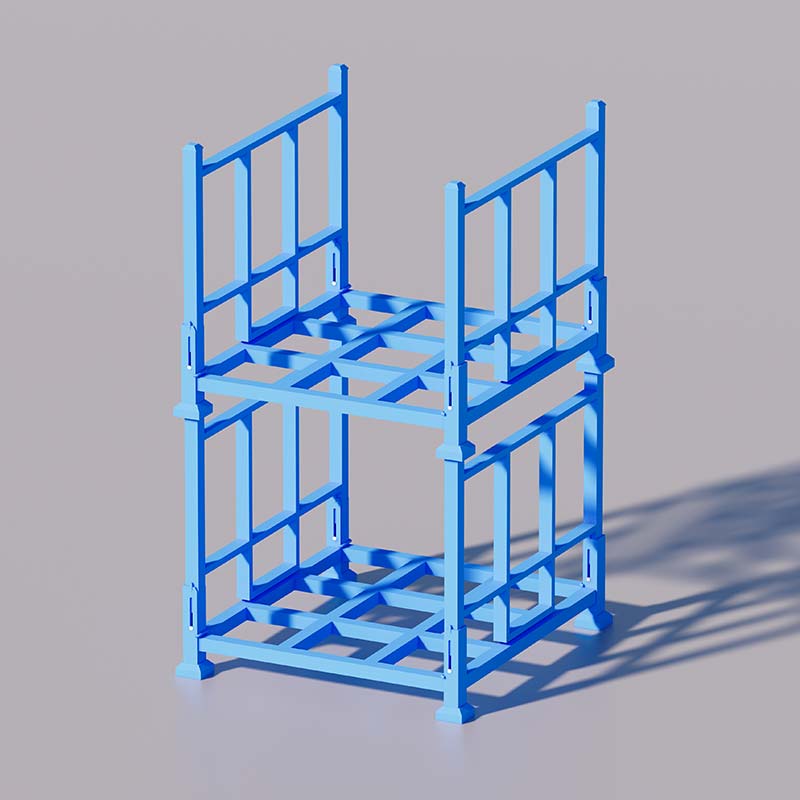

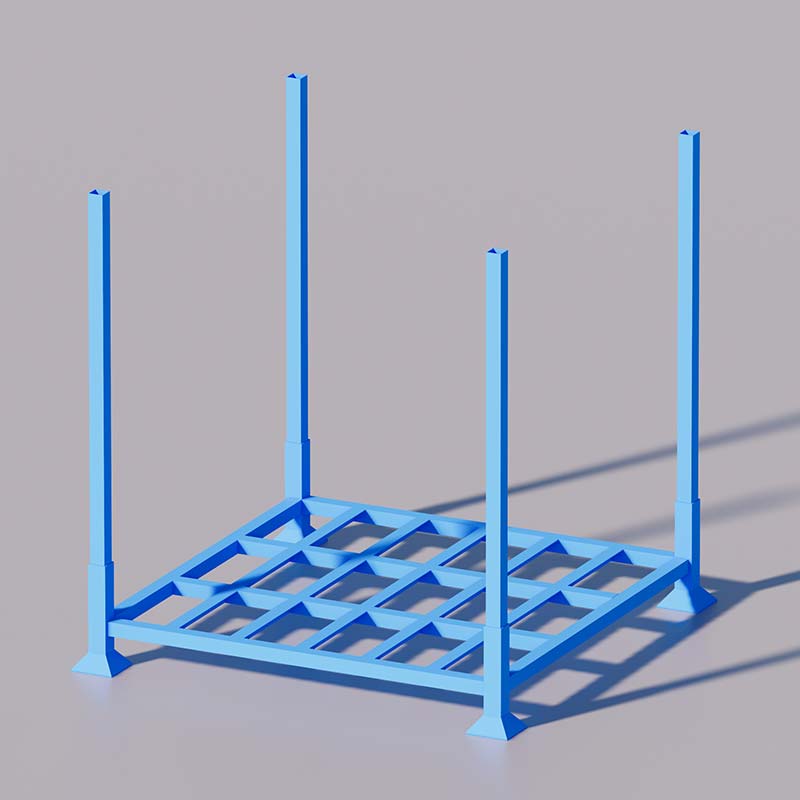

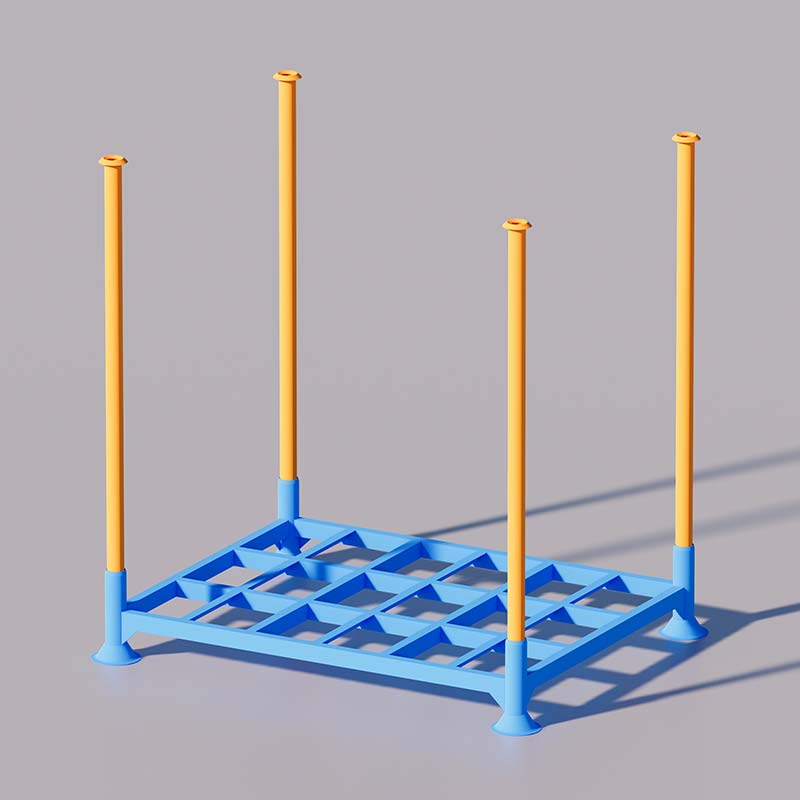

Mobile pallet racks require only simple setup: just insert the four uprights yourself or unfold the folding panels. This straightforward installation process eliminates the need for complex assembly steps, making it accessible even for those with limited technical expertise.

Once set up, these racks are ready to use when paired with a forklift. There’s no need for additional equipment or time-consuming preparations, allowing operations to get underway quickly.

This convenience translates to significant savings in both manpower and material resources. The simplified setup and easy integration with forklifts reduce the labor required for installation and operation, while also cutting down on unnecessary material costs.

If you are unsure, feel free to consult us at any time. We can help install your system safely and efficiently, thereby saving your time and avoiding costly mistakes.

How to organize my warehouse?

Organizing a warehouse effectively requires careful planning. My first step is to categorize items. Group similar products together and decide which are fast-moving. Place high-demand items near the shipping area to reduce retrieval time.

Next, optimize storage space by using the right shelves or racks. For example, use mobile pallet racking for high-density storage. This helps to maximize vertical space and avoid clutter. Keep aisles wide enough for safe forklift movement3 but as narrow as possible to save space.

It’s also important to implement a clear labeling system. Mark each section or rack with labels, barcodes, or digital tracking. This makes inventory management much easier.

Finally, set a routine for regular cleanup and stock checks. This helps discover misplaced items and reduces waste. Good organization boosts efficiency, speeds up processes, and lowers operational costs.

Effective warehouse layout planning4 can transform your storage space from chaos to order in no time. Try to learn from industry best practices and continuously optimize your setup.

Conclusion

Mobile pallet racking offers flexible, space-efficient storage and easy access, making it vital for modern warehouses. Proper organization and system choice can vastly improve your operations.

Explore the advantages of mobile pallet racking systems to enhance your warehouse efficiency and storage capabilities. ↩

Learn about effective stacking techniques to improve safety and space utilization in your warehouse. ↩

Learn best practices for safe forklift movement to enhance safety and efficiency in your warehouse. ↩

Discover tips for planning an effective warehouse layout to transform your storage space. ↩