Proper storage of fabric rolls is critical to preserving their quality and optimizing warehouse space. Fabrics are highly sensitive materials—moisture, excessive pressure, direct light, and dust can all cause irreversible damage, such as discoloration, mildew, fiber breakage, or surface soiling. For warehouses, however, storage management must strike a balance between three core needs: maximizing space utilization, ensuring quick access to inventory, and maintaining strict quality control.

| Classification Dimension | Description | Storage Implications |

|---|---|---|

| Material Type | Group rolls by fiber composition (e.g., cotton, silk, wool, linen) | Addresses unique storage needs such as humidity sensitivity and light exposure requirements. |

| Usage Priority | Sort inventory based on access frequency | High-frequency rolls should be placed near shipping/picking areas for quick retrieval. |

| High-Frequency Inventory | Fabrics for ongoing production or popular orders | Store close to outbound zones to reduce handling time and improve efficiency. |

| Sensitive Fabrics | Fabrics prone to wrinkling or fading (e.g., linen, silk) | Allocate a dedicated dry, climate-controlled zone for protection from humidity and light. |

| Long-Term Inventory | Slow-moving or bulk backup stocks | Store on upper racks to save accessible space; must be sealed and clearly labeled for tracking. |

By prioritizing proper classification, warehouses minimize unnecessary handling of fabric rolls, significantly reduce the risk of damage caused by misplaced storage or repeated movement, and ultimately streamline overall operational workflows—from inventory checks to order fulfillment.

What should I pay attention to when storing fabric rolls?

Proper handling and environmental controls are key. First, avoid stacking soft fabrics too high—pressure can deform rolls. Use supports or separators to distribute weight. Second, shield fabrics from sunlight and dust—cover or store in dark, clean areas. Third, control temperature and humidity to prevent mold. Regular checks and dehumidifiers help.

| Consideration | Action |

|---|---|

| Stacking height | Keep soft fabrics lower; support heavy rolls |

| Light exposure | Store in dark areas; use UV-resistant covers |

| Dust and dirt | Cover fabrics; ensure clean storage spaces |

| Humidity control | Use dehumidifiers; monitor humidity levels |

| Handle carefully | Use gentle handling; avoid dragging or dropping |

In my experience, ignoring these leads to damage. Proper labels, gentle handling, and organized storage prevent this. Staff training and routine inspections catch issues early, saving costs and preserving quality.

How to keep fabric fresh in storage?

Maintaining freshness prevents spoilage. Crucial parts are humidity, light, and pests. Use dehumidifiers to control moisture, and store fabrics in darker areas with UV-resistant covers. Good ventilation helps prevent stale air and mold. Regular pest control prevents damage from insects.

| Preserving freshness | Techniques |

|---|---|

| Humidity control | Use dehumidifiers; keep relative humidity below 60% |

| Light prevention | Store in dark or cover with UV-resistant sheets |

| Ventilation | Use fans or air circulation systems |

| Pest control | Regular cleaning; pest treatments |

| Protective packaging | Vacuum-sealed bags; moisture-proof covers |

Creating designated dry zones with sealed containers works well, especially for natural fibers. Regular environment checks ensure the fabric stays fresh. Neglecting these causes mildew, fading, and fiber deterioration. Consistent monitoring and proactive care preserve fabric integrity and reduce waste.

How to store large rolls of fabric?

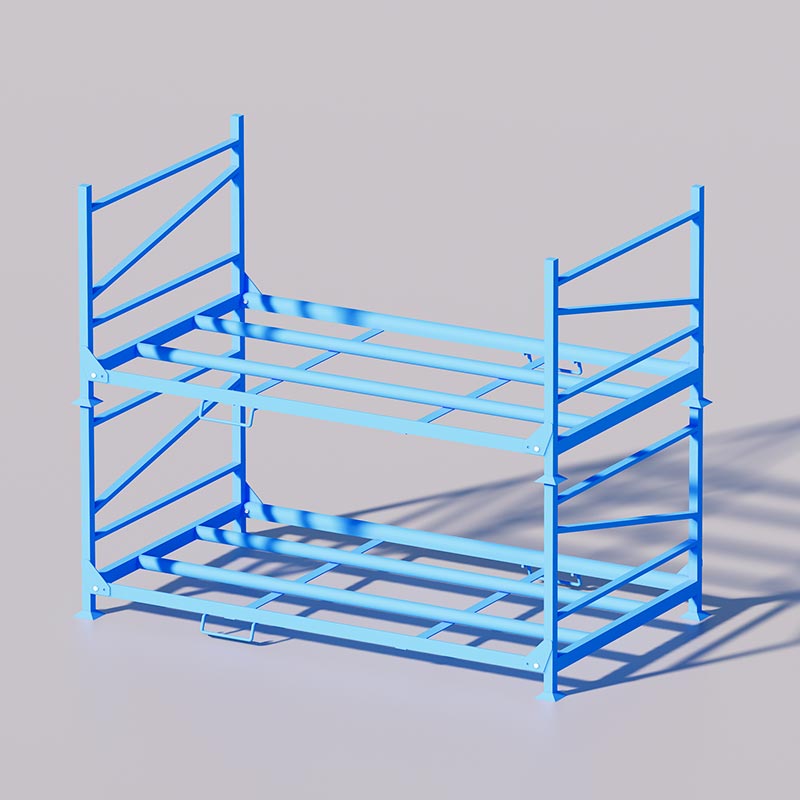

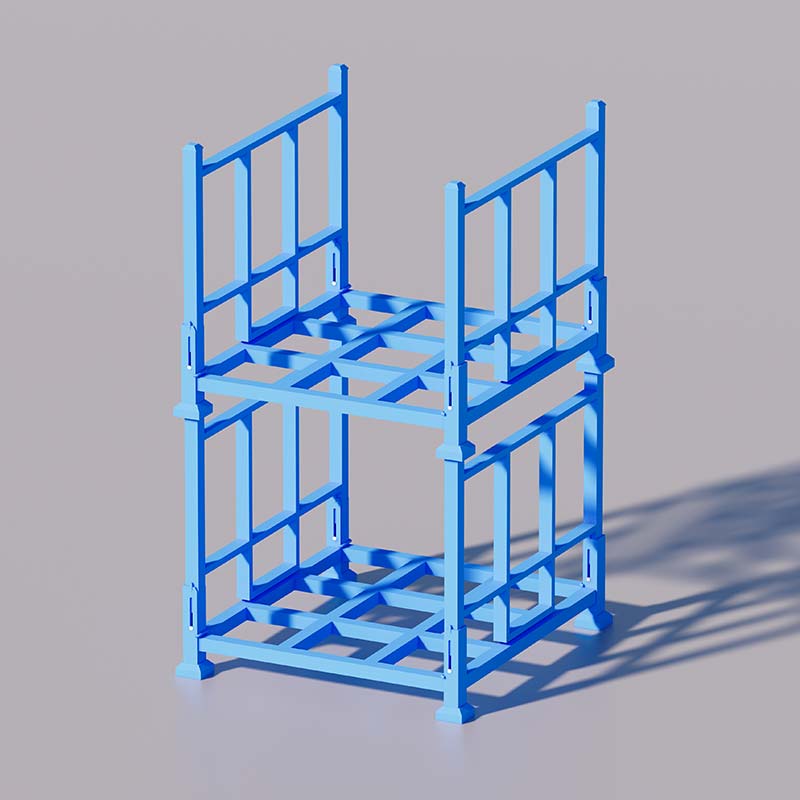

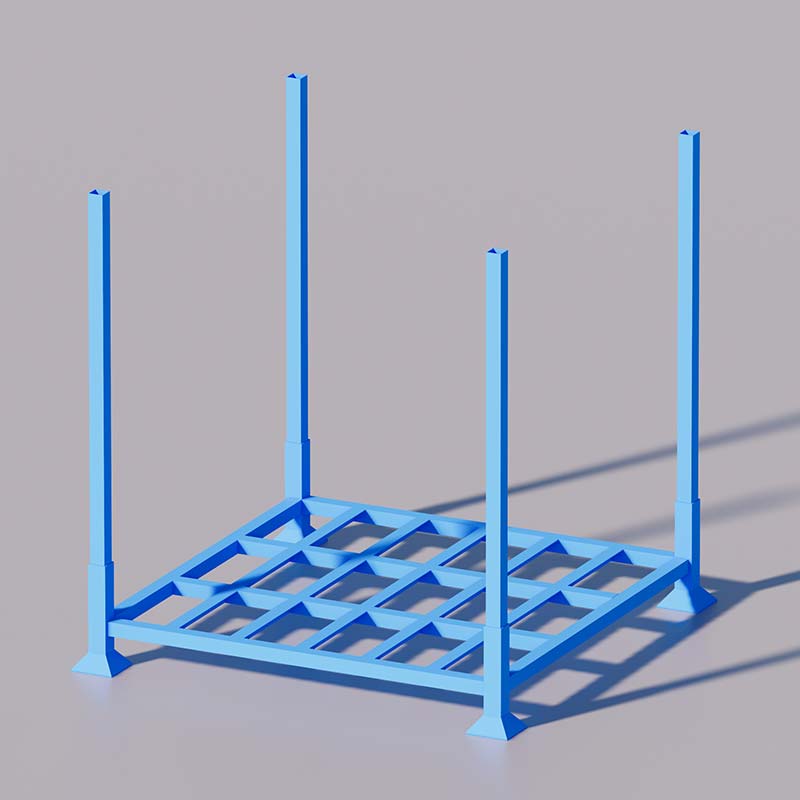

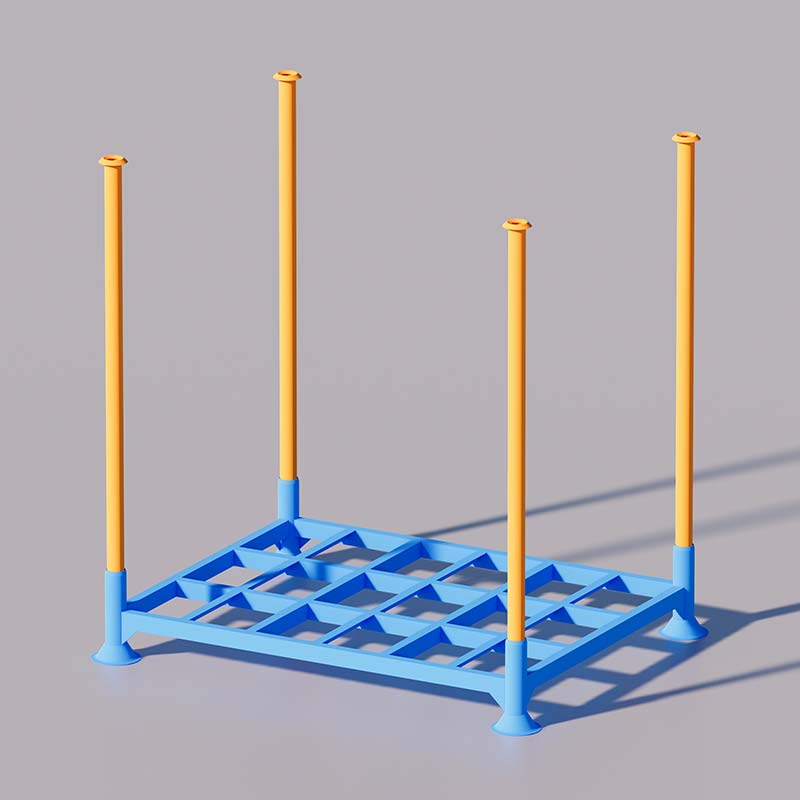

We recommend portable, foldable stacking racks. These racks, equipped with adaptable side panels, effectively prevent fabric rolls from falling during storage and handling. Each rack supports independent movement and handling, allowing for intuitive visibility of incoming and outgoing quantities and fabric classification, eliminating the need for repeated unpacking and verification. This design avoids collision damage during handling and significantly reduces labor and material costs. Crucially, when not in use, the racks can be stacked with foldable panels, eliminating the need for additional space and significantly improving overall warehouse space utilization.

In conclusion, effective storage is built on classification, controlled environment, quality tools, and safety. It helps preserve fabric quality, improve warehouse flow, and save space.